Multi Wire Saws M/C

WEC acts as an agent of the new Multi Wire Saws Machine (T-8331A) for diamond wire dedicated machine, which is designed by Toyo Advanced Technologies Co., Ltd. By using the unique technology and combining the characteristics of diamond wire, this Multi Wire Saws Machine can improve the cutting completion quality, shorten half of the cutting time and enhance the productivity.

Application

This product can be applied to hard and brittle materials such as sapphire, silicon carbide (SiC), gallium nitride (GaN), etc.

Specification

Specification |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Item (Model No.) | UF-700 | |||||||||||

| Workpiece dimension | Max. 176 (H) X 176 (W) X 300 (D) | |||||||||||

| Wire running speed | Max. 1800 m/min | |||||||||||

| Wire guide | Ø220 mm | |||||||||||

| Number of wire guides | Single Wire | |||||||||||

| Rocking degree | ± 3 | |||||||||||

| Z Table stroke | 200 mm | |||||||||||

| Z In feed rate | 0.01 ~ 150 mm/min | |||||||||||

| Wire diameter | Ø 0.15 ~ 0.42 mm | |||||||||||

| Wire Tension | Max. 60 N or less | |||||||||||

| Volume of the tank | 200 L | |||||||||||

| Installation dimension | W3000 X D1900 X H2200 mm | |||||||||||

| Machine weight | 9.0 tons | |||||||||||

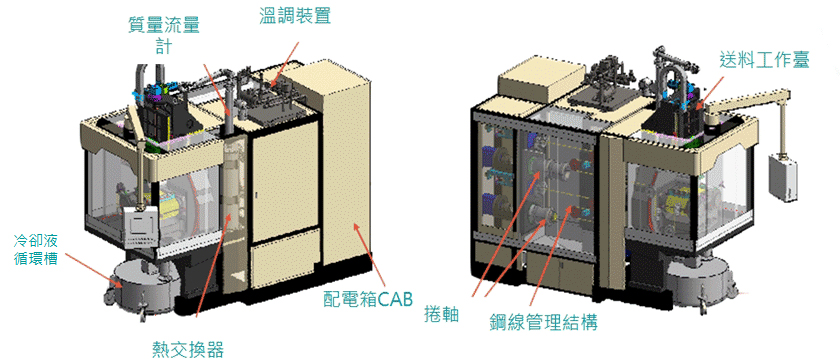

• T-8331A is applied to cut up to φ6-inch and 300mm length ingots • Double productivity (φ4-inch only needs 6 hours)) • High-precision processing of TTV 10μm and Bow 10μm • Low running cost and wire consumption (15m/wafer for φ4-inch sapphire ingot) • The rocking column mechanism holds the wire guides is more effective for cutting hard and brittle materials • Excellent rigid structure keeps the rocking column mechanism more stable • Twist-free wire management system can maintain the wire torque, skewing balance and the wire tension control when the wire is under the high-speed operation • High-speed and accurate process enable to assure the 1,200mm/min. of high wire speed and 1.5 sec. of high-speed reciprocating acceleration/deceleration cutting cycle under the heavy-loaded tension • The integrated cutting position can be set by different work conditions, such as wire speed, rocking speed, angle, etc